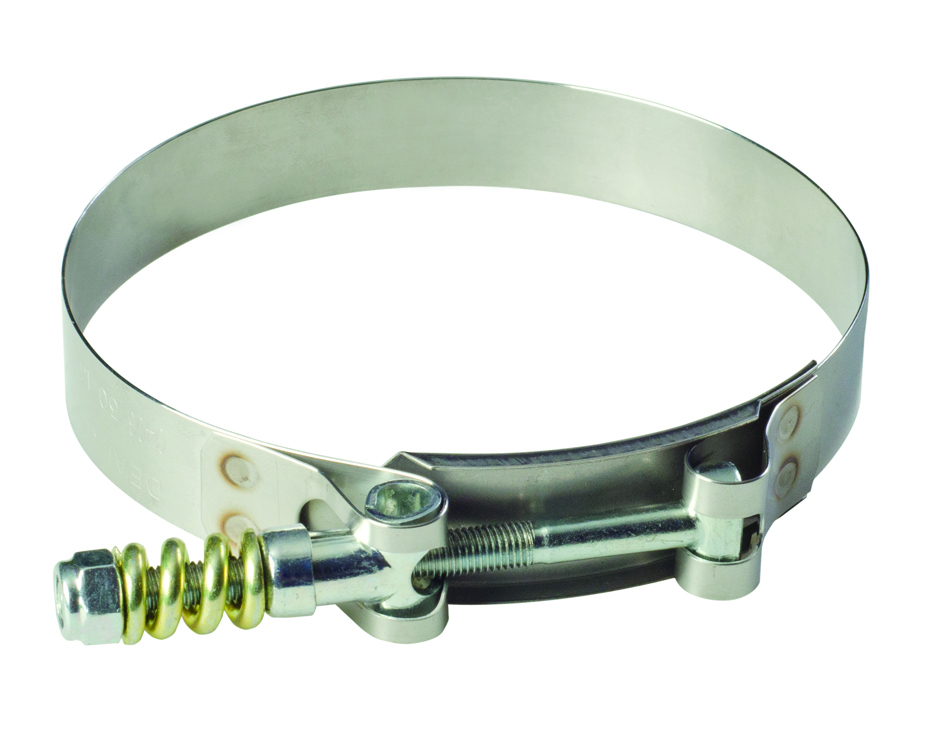

CONSTANT TENSION CLAMPS

2584 Series

Constant tension clamps are an ideal solution for silicone coolant hose, heater hose, and marine connections. Constant tension clamps provide a uniform 360° seal. They are constructed to respond to constant temperature fluctuations and resist extreme temperatures.

BENEFITS

- Lined Clamp Design

- Belleville Spring and Clamp Construction is Designed to Respond to Constant Temperature Fluctuations

- Ideal for Silicone Coolant Hose, Heater Hose, and Marine Connections

- Provides Uniform 360° Seal

APPLICATION

- For charge air connector (CAC) applications

CONSTRUCTION

- All 300 grade stainless steel constant tension lined clamps

- Hex Head: 3/8”

- Band Width: 5/8”

- Resists salt water and may be used in marine applications

- Liner protects the hose surface and prevents silicone from shearing through band notches

ORDER NOW

Manufacturer requires minimum order quantity

2584 SERIES: CONSTANT TENSION CLAMPS

| Part Number | Min. Dia.(in.) | Max. Dia.(in.) | Min. Dia.(mm) | Max. Dia.(mm) | PackSize | WeightLBS - Per 10 |

|---|---|---|---|---|---|---|

| FLX2584-0175 | 1 | 1.75 | 25 | 45 | 10 | 2 |

| FLX2584-0212 | 1.25 | 2.13 | 32 | 54 | 10 | 2 |

| FLX2584-0262 | 1.75 | 2.63 | 45 | 67 | 10 | 2 |

| FLX2584-0312 | 2.25 | 3.13 | 57 | 79 | 10 | 2 |

| FLX2584-0362 | 2.75 | 3.63 | 70 | 92 | 10 | 2 |

| FLX2584-0412 | 3.25 | 4.13 | 83 | 105 | 10 | 2.5 |

| FLX2584-0462 | 3.75 | 4.63 | 95 | 117 | 10 | 2.5 |

| FLX2584-0512 | 4.25 | 5.13 | 108 | 130 | 10 | 2.5 |

| FLX2584-0562 | 4.75 | 5.63 | 121 | 143 | 10 | 2.5 |

| FLX2584-0612 | 5.25 | 6.13 | 133 | 155 | 10 | 2.5 |

| FLX2584-0662 | 5.75 | 6.63 | 146 | 168 | 10 | 3 |

| FLX2584-0712 | 6.25 | 7.13 | 159 | 181 | 10 | 3 |

| FLX2584-0762 | 6.75 | 7.63 | 172 | 193 | 10 | 3 |

| FLX2584-0812 | 7.25 | 8.13 | 184 | 206 | 10 | 3 |

| FLX2584-0862 | 7.75 | 8.63 | 197 | 219 | 10 | 3 |

| FLX2584-0912 | 8.25 | 9.13 | 210 | 232 | 10 | 3.5 |

COOLANT AND HEATER HOSE CLAMPING INSTRUCTIONS:

Worm gear or constant torque type stainless steel clamps with inner liner are recommended for silicone heater and coolant hose. Initial clamp torque should be 40 inch-lbs. If re-torqueing is required, it should be limited to 20 inch-lbs. Do not use serrated, slotted, or wire type clamps.