LEADING INNOVATION

Flexfab’s consistent investment into advanced development processes is setting us apart as a world technology leader. We are leading the way to more efficient processes, more precise tooling, and more cost-effective products every day. Learn how Flexfab's research and development is advancing our capabilities every day.

Learn More About Each of Our Technology Capabilities Below.

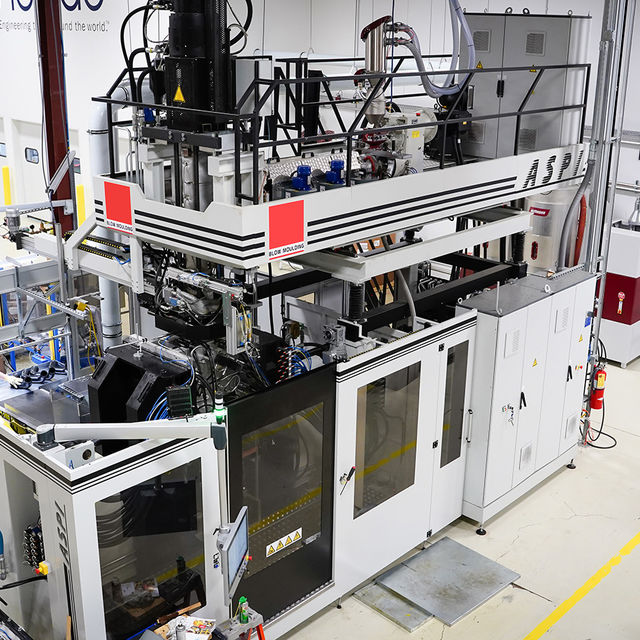

Blow Molding

State-of-the-art blow molding technology allows us to design complex hollow plastic shapes in 2D and 3D with controlled wall thickness and limited waste.

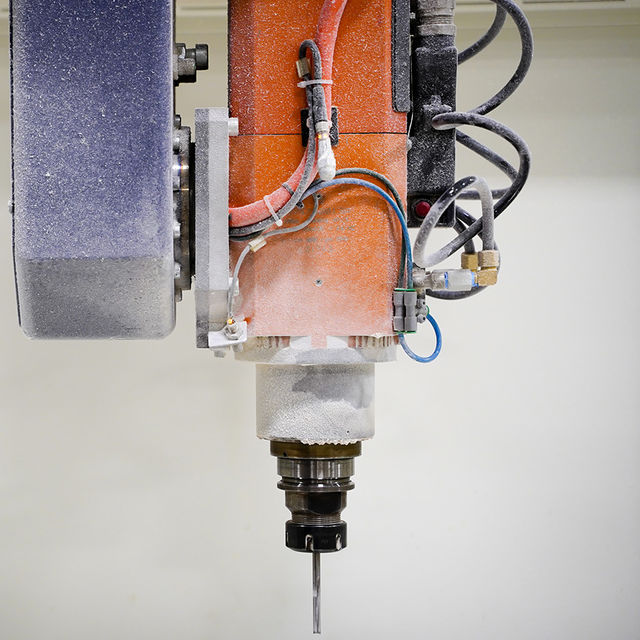

Robotics

Flexfab’s venture into robotics has yielded a wide range of benefits. Our robot groups have eliminated human error and saved us space, time and labor costs.

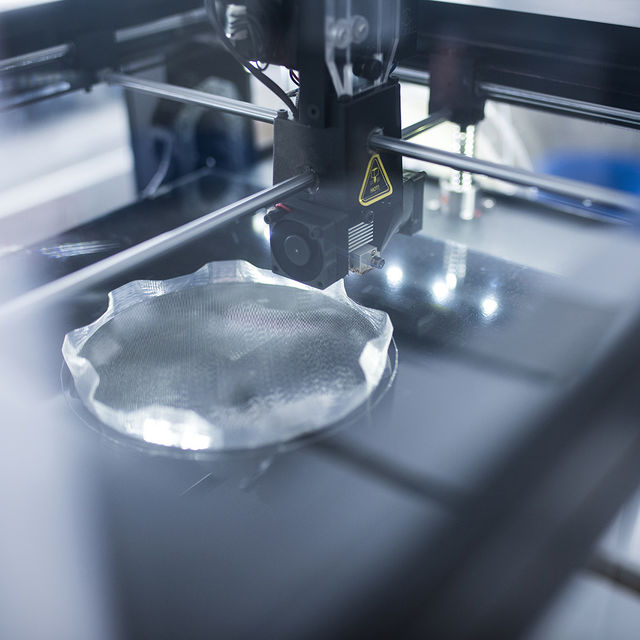

3D Printing

Flexfab’s consistent investment into advanced development processes is setting us apart as a world technology leader

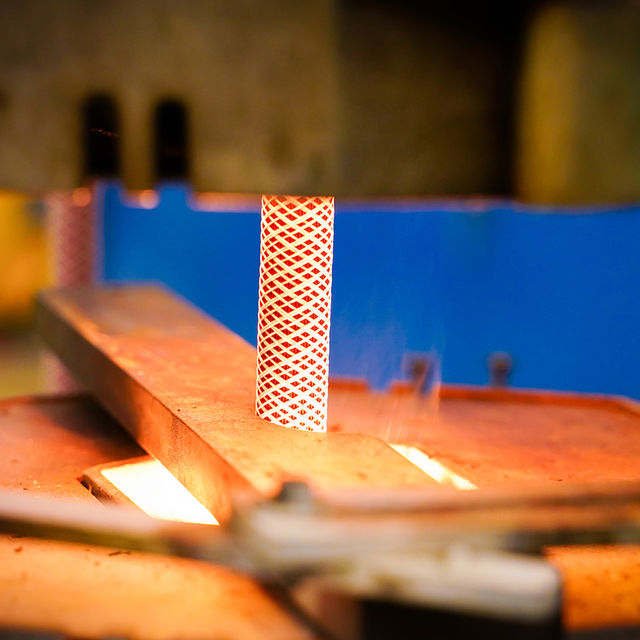

RTL

When you engineer parts that are lighter than aluminum but durable enough to withstand the grueling demands of today’s large engines, your only option is RTL

RFP

RFP is quickly emerging as a top material of choice for parts manufacturing. RFP parts are lightweight, durable, self-insulating, and can be easily incorporated into assemblies with metal and flexible components

Assemblies

Flexfab’s engineered assemblies replace three parts with one, making installation and replacement easier and more efficient.

Co-Extrusion

Co-extrusion is the future of fabrication technology and our research has put us years ahead of the market.